Maximize Filtration Efficiency with Filter Presses

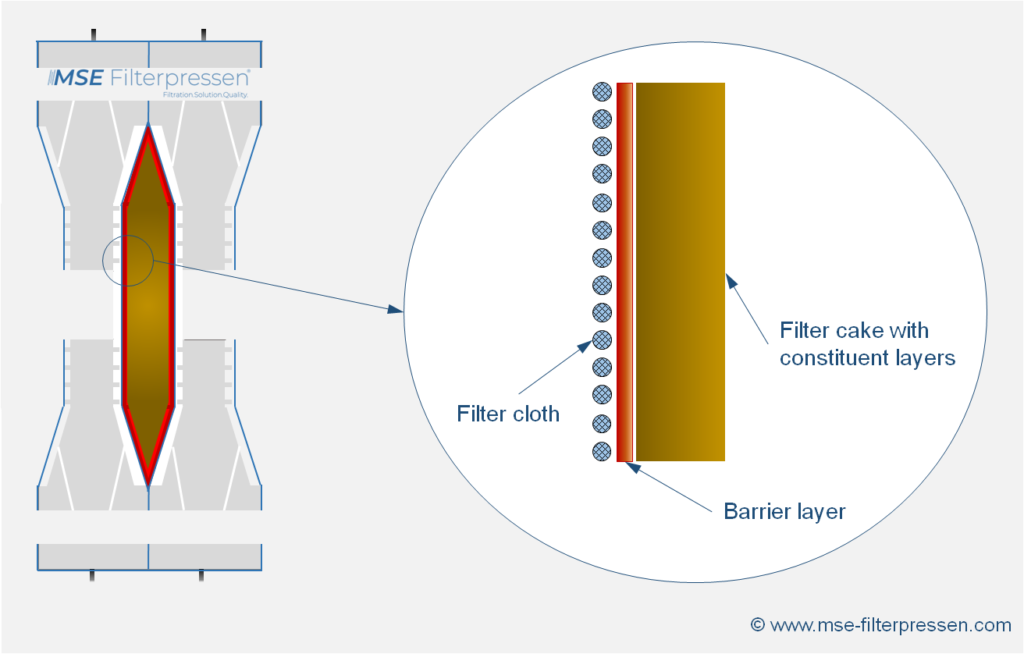

Filter presses are an essential tool for industries that require efficient solid-liquid separation. They work by applying pressure to a mixture of solids and liquids, forcing the liquid to pass through a filter cloth while retaining the solids. This article will explore the benefits of using the presses, including increased efficiency, reduced operating costs, and improved product quality. With the right setup and maintenance, filter presses can provide a reliable and cost-effective solution for your filtration needs.

Introduction

Filter presses are popular in a wide range of industries, including chemical, pharmaceutical, food, and mining. They design to separate solids from liquids using pressure and filter cloth. By applying pressure to the mixture, the liquid forces through the filter cloth, leaving behind the solids. This process is famous for solid-liquid separation, and it is critical in many industrial processes.

Benefits of Using Filter Presses

Filter presses offer several advantages over other filtration methods. One of the main benefits is increased efficiency. Because the presses apply pressure to the mixture, they can remove a higher percentage of solids from the liquid than other methods. This means that less liquid is wasted, reducing operating costs and improving overall product quality.

Another benefit of using filter presses is the ability to customize the filtration process. By adjusting the pressure, temperature, and filter cloth, you can tailor the process to meet your specific needs. This level of customization can help improve product quality and reduce waste.

Types of Filter Presses

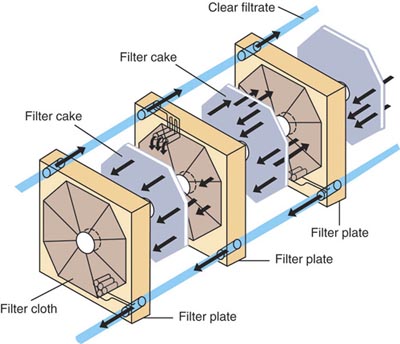

There are several types of filter presses available, each with its unique features. The most common types include recessed plate presses, membrane filter presses, and plate and frame filter presses. Recessed plate presses are the most basic type of filter press. They consist of a series of plates with filter cloths between them.

Membrane filter presses are similar to recessed plate filter presses but use a flexible membrane instead of a solid plate. The membrane inflates with air or water, increasing the pressure on the mixture and improving filtration efficiency.

Plate and frame presses are another type of filter press that uses a series of plates and frames to separate solids from liquids. The plates cover with filter cloths, and the mixture pumps into the press. As pressure is applied, the liquid is forced through the filter cloth, leaving the solids behind.

Maintenance and Troubleshooting

Proper maintenance is essential to ensure the longevity and efficiency of your filter press. Regular cleaning and inspection of the filter cloths and plates can help prevent damage and ensure optimal filtration performance. Additionally, checking the hydraulic system, pumps, and valves can help identify and address any issues before they cause significant problems.

If you experience problems with your filter press, there are several troubleshooting steps you can take. Common issues include leaking plates, clogged filter cloths, and low filtration efficiency. By identifying the cause of the problem, you can take steps to address and correct it, ensuring that your filter press continues to operate at peak performance.

Conclusion:

Filter presses are an essential tool for industries that require efficient solid-liquid separation. They offer several benefits, including increased efficiency, reduced operating costs, and improved product quality. With the right setup and maintenance, filter presses can provide a reliable and cost-effective solution for your filtration needs. Whether you’re in the chemical, pharmaceutical, food, or mining industry, a filter press can help you maximize your filtration efficiency and improve your bottom line.